PDFWAC 296-155-33910

Adjustable hardware.

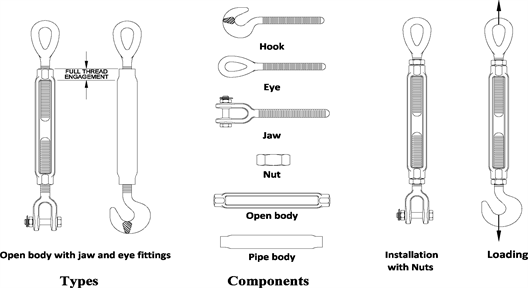

(1) Turnbuckles. You must follow these rigging practices for turnbuckles:

(a) Locking nuts, if used, must be compatible with the threads of the turnbuckle end. (See Figure 19, Turnbuckle Types.)

(b) For long-term installations, you must secure turnbuckles in a way that prevents unscrewing.

(c) Turnbuckle end fitting threads must be fully engaged in the body threads.

(d) Components, including pins, bolts, nuts, or cotter pins used with jaw ends, must be in good working condition prior to use.

Notes: | • See Figure 19 for types of turnbuckles covered by this rule. |

• Pipe bodies conceal the length of thread engagement. Verify full engagement before loading. (See Figure 19.) |

|

Figure 19 Turnbuckle Types |

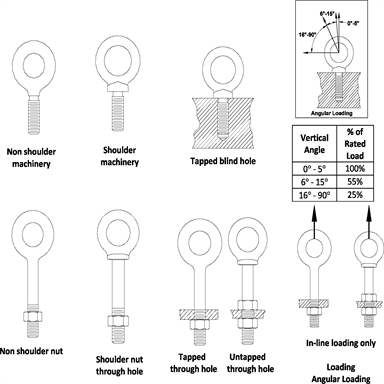

(2) Eyebolts. You must follow these rigging practices for eyebolts:

(a) Eyebolts not shouldered to the load must only be used for in-line loads. (See Figure 20, Eyebolts.)

(b) You must only use shoulder eyebolts for angular lifting.

(i) The shoulder must be flush and securely tightened against the load.

(ii) You must reduce the working load limit (WLL) as shown in Figure 31.

(iii) For angular lifts, the plane of the eye must be aligned with the direction of loading. If needed, flat washers can be used under the shoulder to position the plane of the eye. (See Figure 20.)

(c) When using eyebolts in a tapped blind hole, the effective thread length must be at least one and 1/2 times the diameter of the bolt for engagement in steel. (See Figure 20.) For other engagements, or engagements in other materials, contact the eyebolt manufacturer or a qualified person.

(d) When using eyebolts in a tapped through-hole of less than one diameter thickness, a nut must be used under the load, and must be fully engaged and tightened securely against the load. (See Figure 20.)

(e) When eyebolts are used in an untapped through-hole, the nut under the load must be fully engaged. If the eyebolt is not shouldered to the load, a second nut on top of the load should be used if possible. (See Figure 20.)

Note: | See Figure 20 for examples of eyebolts covered by this rule. |

|

Figure 20 Eyebolts |

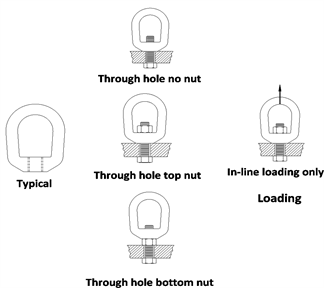

(3) Eye nuts. You must follow these rigging practices for eye nuts (see Figure 21, Eye Nuts):

(a) The threads of eye nuts must be fully engaged;

(b) Eye nuts must only be used for in-line loads;

(c) Components must be in good working condition prior to use.

|

Figure 21 Eye Nuts |

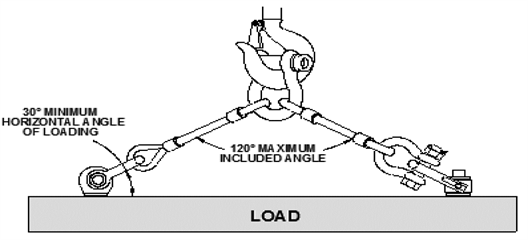

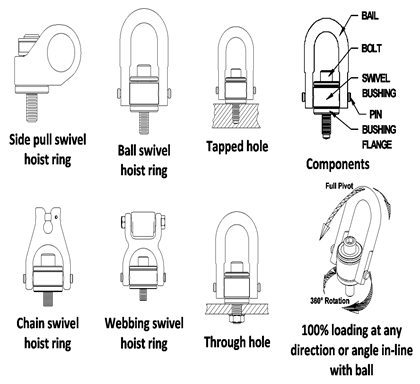

(4) Swivel hoist rings. You must follow these rigging practices for swivel hoist rings:

(a) The swivel hoist ring working load limit (WLL) must meet or exceed the anticipated angular rigging tension. (See Figure 22, Angle of Loading.)

(b) Swivel hoist rings must be tightened to the torque specifications of the manufacturer.

(c) The swivel hoist ring must be free to rotate and pivot without interference during lifting. (See Figure 23, Swivel Hoist Rings.)

(d) The load applied to the swivel hoist ring must be centered in the bail to prevent side loading.

(e) Any attached lifting component must be narrower than the inside width of the bail to avoid spreading.

(f) When using swivel hoist rings in a threaded-hole, the effective thread length must be one and 1/2 times the diameter of the bolt for steel. (See Figure 23.) For other thread engagements or engagement in other materials, contact the manufacturer or a qualified person.

(g) When using swivel hoist rings in a through-hole application, a nut and washer must be used. A washer and nut must be in accordance with the manufacturer's recommendations. The nut must be fully engaged. (See Figure 23.)

(h) The bushing flange must fully contact the load surface. (See Figure 23.)

(i) Spacers or washers must not be used between the bushing flange and the mounting surface of the load being lifted.

Note: | See Figure 23 for examples of swivel hoist rings covered by this rule. |

|

Figure 22 Angle of Loading (Adjustable Hardware) |

|

Figure 23 Swivel Hoist Rings |

[Statutory Authority: RCW 49.17.010, 49.17.040, 49.17.050, 49.17.060. WSR 16-09-085, § 296-155-33910, filed 4/19/16, effective 5/20/16. Statutory Authority: RCW 49.17.010, 49.17.040, 49.17.050, 49.17.060 and chapter 49.17 RCW, and 29 C.F.R. 1926, Subpart CC. WSR 13-02-068, § 296-155-33910, filed 12/31/12, effective 2/1/13.]