Chapter 296-876 WAC

Last Update: 4/21/20LADDERS, PORTABLE AND FIXED

WAC Sections

| HTMLPDF | 296-876-099 | Definitions. |

| HTMLPDF | 296-876-100 | Scope. |

| HTMLPDF | 296-876-150 | Training. |

| HTMLPDF | 296-876-15005 | Training. |

| HTMLPDF | 296-876-200 | Design and construction. |

| HTMLPDF | 296-876-20005 | Design and construction. |

| HTMLPDF | 296-876-300 | Ladder care. |

| HTMLPDF | 296-876-30005 | Condition and inspection. |

| HTMLPDF | 296-876-30010 | Repair. |

| HTMLPDF | 296-876-30015 | Storage. |

| HTMLPDF | 296-876-30020 | Transport. |

| HTMLPDF | 296-876-400 | Portable ladder use. |

| HTMLPDF | 296-876-40005 | Designed use. |

| HTMLPDF | 296-876-40010 | Workplace activities or traffic. |

| HTMLPDF | 296-876-40015 | Support. |

| HTMLPDF | 296-876-40020 | Set-up. |

| HTMLPDF | 296-876-40025 | Climbing and descending. |

| HTMLPDF | 296-876-40030 | Getting on and off ladders at upper levels. |

| HTMLPDF | 296-876-40035 | Exposed electrical hazards. |

| HTMLPDF | 296-876-40040 | Persons on ladders. |

| HTMLPDF | 296-876-40045 | Multisection ladders. |

| HTMLPDF | 296-876-40050 | Self-supporting ladders. |

| HTMLPDF | 296-876-500 | Fixed ladder design and construction installed on or after December 1, 2006. |

| HTMLPDF | 296-876-50010 | Design and construction—Fixed ladders installed on or after December 1, 2006. |

| HTMLPDF | 296-876-600 | Fixed ladder design and construction installed before December 1, 2006. |

| HTMLPDF | 296-876-60005 | Design and construction—Fixed ladders installed before December 1, 2006. |

| HTMLPDF | 296-876-60010 | Design loads. |

| HTMLPDF | 296-876-60015 | Pitch. |

| HTMLPDF | 296-876-60020 | Welding. |

| HTMLPDF | 296-876-60025 | Ladder surfaces. |

| HTMLPDF | 296-876-60030 | Rungs, cleats and steps. |

| HTMLPDF | 296-876-60035 | Side rails. |

| HTMLPDF | 296-876-60040 | Clearances. |

| HTMLPDF | 296-876-60045 | Step-across distance. |

| HTMLPDF | 296-876-60050 | Extensions and grab bars. |

| HTMLPDF | 296-876-60055 | Hatches. |

| HTMLPDF | 296-876-60060 | Platforms. |

| HTMLPDF | 296-876-60065 | Protective structures and equipment. |

| HTMLPDF | 296-876-60070 | Cages. |

| HTMLPDF | 296-876-60075 | Wells. |

| HTMLPDF | 296-876-60080 | Ladder safety devices. |

| HTMLPDF | 296-876-700 | Fixed ladders inspection and maintenance. |

| HTMLPDF | 296-876-70005 | Protection against corrosion and deterioration. |

| HTMLPDF | 296-876-70010 | Inspection and repair. |

| HTMLPDF | 296-876-800 | Fixed ladder use. |

| HTMLPDF | 296-876-80005 | Designed load. |

| HTMLPDF | 296-876-80010 | Climbing and descending. |

| HTMLPDF | 296-876-90005 | Step bolt requirements. |

| HTMLPDF | 296-876-90010 | Manhole step requirements. |

| HTMLPDF | 296-876-910 | Mobile ladder stands and mobile ladder stand platforms. |

| HTMLPDF | 296-876-91005 | General requirements. |

| HTMLPDF | 296-876-91010 | Design requirements for mobile ladder stands. |

| HTMLPDF | 296-876-91015 | Design requirements for mobile ladder stand platforms. |

DISPOSITION OF SECTIONS FORMERLY CODIFIED IN THIS TITLE

| 296-876-50005 | Training. [Statutory Authority: RCW 49.17.010, 49.17.040, 49.17.050, 49.17.060. WSR 05-20-068, § 296-876-50005, filed 10/4/05, effective 1/1/06.] Repealed by WSR 06-16-020, filed 7/24/06, effective 12/1/06. Statutory Authority: RCW 49.17.010, 49.17.040, 49.17.050, 49.17.060. |

| 296-876-900 | Definitions. [Statutory Authority: RCW 49.17.010, 49.17.040, 49.17.050, 49.17.060. WSR 06-16-020, § 296-876-900, filed 7/24/06, effective 12/1/06.] Repealed by WSR 14-09-095, filed 4/22/14, effective 7/1/14. Statutory Authority: RCW 49.17.010, 49.17.040, 49.17.050, 49.17.060, and chapter 49.17 RCW. |

PDF296-876-099

Definitions.

Cage. An enclosure mounted on the side rails of a fixed ladder or fastened to a structure behind the fixed ladder that is designed to surround the climbing space of a fixed ladder. It may also be called a "cage guard" or "basket guard."

Carrier. The track of a ladder safety system that consists of a flexible cable or rigid rail attached, or immediately adjacent, to a fixed ladder.

Cleat. See "rung."

Combination ladder. See "special-purpose ladder."

Competent person. Is an individual knowledgeable of ladders, including the manufacturer's recommendations and instructions for the proper use, inspection, and maintenance; and who is capable of identifying existing and potential ladder hazards; and who has the authority to take prompt corrective action to eliminate those hazards; and who is knowledgeable of the rules contained in this part regarding the installation, use, inspection, and maintenance of ladders.

Equivalent. Alternative design, material, or method to protect against a hazard. You have to demonstrate it provides an equal or greater degree of safety for employees than the method, material, or design specified in the rule.

Extension ladder. A nonself-supporting portable ladder which is adjustable in length.

Failure. The ladder or ladder component loses the ability to carry the load, breaks, or separates into component parts.

Fastenings. Devices to attach a ladder to a structure, building, or equipment.

Fixed ladder. A ladder permanently attached to a structure, building, or equipment. Fixed ladders include individual-rung ladders, but not ship stairs, step bolts, or manhole steps.

Grab bar. An individual horizontal or vertical handhold installed to provide access above the height of the ladder.

Job-made ladder. A ladder that is made, not commercially manufactured, to fit a specific job situation. They are for temporary use until a particular phase of construction is completed or until permanent stairways or fixed ladders are ready to use.

Individual-rung/step ladder. A fixed ladder consisting of individual steps or rungs mounted directly to the side or wall of the structure, building, or equipment. An individual-rung ladder does not include manhole steps.

Ladder. A device having steps, rungs, or cleats that can be used to climb or descend.

Ladder safety device. Any device, other than a cage or well, designed to eliminate or reduce the possibility of falling from a ladder. A ladder safety device usually consists of a carrier, safety sleeve, lanyard, connectors, and body harness.

Ladder type. The designation that identifies the maximum intended load (working load) of the ladder. Ladder types are as follows:

Duty Rating | Ladder Type | Use | Maximum Intended Load (pounds) |

Extra Heavy-Duty | IA | Industry, utilities, contractors | 300 |

Heavy-Duty | I | Industry, utilities, contractors | 250 |

Medium-Duty | II | Painters, offices, light maintenance | 225 |

Light-Duty | III | General household use | 200 |

Landing. Any area such as the ground, roof, or platform that provides access or egress to a ladder.

Manhole steps. Steps that are individually attached to, or set into, the wall of a manhole structure.

Maximum intended load. The total load of all persons, equipment, tools, materials, transmitted loads, and other loads reasonably anticipated to be applied to a ladder or ladder component at any one time. Sometimes referred to as working load.

Mobile. Manually propelled or moveable.

Mobile ladder stand (ladder stand). A mobile, fixed-height, self-supporting ladder that usually consists of wheels or casters on a rigid base and steps leading to a top step. A mobile ladder stand also may have handrails and is designed for use by one employee at a time.

Mobile ladder stand platform. A mobile, fixed-height, self-supporting unit having one or more standing platforms that are provided with means of access or egress.

Pitch. The included angle between the horizontal and the ladder, measured on the opposite side of the ladder from the climbing side.

Portable ladder. A ladder that can be readily moved or carried.

Qualified. Describes a person who, by possession of a recognized degree, certificate, or professional standing, or who by extensive knowledge, training, and experience has successfully demonstrated the ability to solve or resolve problems relating to the subject matter, the work, or the project.

Reinforced plastic. A plastic that has high-strength fillers embedded in the base resin to increase strength.

Reinforced plastic ladder. A ladder whose side rails are reinforced plastic. The crosspieces, hardware, and fasteners may be made of metal or other suitable material.

Rung. A ladder crosspiece used in climbing or descending. Also called a cleat or step.

Side-step ladder. A fixed ladder that requires an employee to step sideways from the ladder in order to reach a walking-working surface, such as a landing.

Single ladder. A nonself-supporting portable ladder, nonadjustable in length, consisting of one section. The size is designated by the overall length of the side rail.

Single-rail ladder. A portable ladder with crosspieces mounted on a single rail. Single-rail ladders are prohibited from use.

Special-purpose ladder. A portable ladder that by design can be used as a stepladder, extension ladder, trestle ladder, stairway ladder, etc., in order to adapt the ladder to special or specific uses. The components of a combination ladder also may be used separately as a single ladder.

Step. See "rung."

Stepladder. A self-supporting portable ladder, nonadjustable in length, with flat steps and hinged at the top. The size is designated by the overall length of the ladder measured along the front edge of the side rails.

Step bolt. (Also referred to as "pole step") means a bolt or rung attached at intervals along a structural member used for foot placement and as a handhold when climbing or standing.

Stepstool. A self-supporting, portable ladder that has flat steps and side rails. For purposes of the final rule, stepstool includes only those ladders that have a fixed height, do not have a pail shelf, and do not exceed thirty-two inches (81 cm) in overall height to the top cap, although side rails may extend above the top cap. A stepstool is designed so an employee can climb and stand on all of the steps and the top cap.

Through ladder. A fixed ladder that allows an employee to step between the side rails of the ladder to reach a walking-working surface, such as a landing.

Trestle ladder. A self-supporting portable ladder, nonadjustable in length, consisting of two sections hinged at the top to form equal angles with the base. The size is designated by the length of the side rails measured along the front edge.

Well. A permanent, complete walled enclosure around a fixed ladder.

Working length. The length of a nonself-supporting ladder, measured along the rails, from the base support point of the ladder to the point of bearing at the top.

PDF296-876-100

Scope.

This chapter applies to portable and fixed ladders (including job-made wooden ladders), mobile ladder stands, and mobile ladder stand platforms. For fall arrest harness, rope/cable grab, and similar requirements related to ladder safety systems which are used on fixed ladders (see the unified fall protection rule, chapter 296-880 WAC).

EXEMPTION: | This chapter does not apply to: |

1. Portable ladders used by the fire services for fire combat that are covered by safety standards for firefighters, chapter 296-305 WAC; | |

2. Ladders used in other emergency training, and operations like rescue, and tactical law enforcement; | |

3. Agriculture activities covered by safety standards for agriculture, chapter 296-307 WAC; | |

4. Ladders designed into, or is an integral part of machines or equipment; | |

[Statutory Authority: RCW 49.17.010, 49.17.040, 49.17.050, 49.17.060 and chapter 49.17 RCW. WSR 20-09-146, § 296-876-100, filed 4/21/20, effective 10/1/20. Statutory Authority: RCW 49.17.010, 49.17.040, 49.17.050, and 49.17.060. WSR 16-23-141, § 296-876-100, filed 11/22/16, effective 12/23/16. Statutory Authority: RCW 49.17.010, 49.17.040, 49.17.050, 49.17.060, and chapter 49.17 RCW. WSR 14-09-095, § 296-876-100, filed 4/22/14, effective 7/1/14. Statutory Authority: RCW 49.17.010, 49.17.040, 49.17.050, 49.17.060. WSR 06-16-020, § 296-876-100, filed 7/24/06, effective 12/1/06; WSR 05-20-068, § 296-876-100, filed 10/4/05, effective 1/1/06.]

PDF296-876-150

Training.

Your responsibility: To train employees who use ladders.

You must meet the requirements... | in this section: |

Training | WAC 296-876-15005 |

PDF296-876-15005

Training.

(1) You must train employees to recognize ladder hazards and the procedures to minimize these hazards.

(2) You must have a competent person train employees that use ladders in at least the following topics:

(a) The proper construction, use, placement, and care in handling ladders.

(b) The maximum intended load capacities of ladders that are used.

(c) The requirements of this chapter.

(3) You must retrain employees as necessary to make sure they know and understand the content of the original training.

PDF296-876-200

Design and construction.

Summary

Your responsibility: To make sure portable ladders meet design and construction requirements.

You must meet the requirements... | in this section: |

Design and construction | WAC 296-876-20005 |

PDF296-876-20005

Design and construction.

Important:

Design and construction requirements of this section do not apply to special purpose ladders.

(1) You must make sure portable ladders and job-made wooden ladders manufactured on or after January 1, 2006, meet the design and construction requirements and specifications of the appropriate American National Standards Institute (ANSI) standard:

(a) ANSI A14.1-2000, American National Standard for Ladders-Portable Wood-Safety Requirements.

(b) ANSI A14.2-2000, American National Standard for Ladders-Portable Metal-Safety Requirements.

(c) ANSI A14.5-2000, American National Standard for Ladders-Portable Reinforced Plastic-Safety Requirements.

(d) ANSI A14.4-2002, American National Standard Safety Requirements for Job-Made Wooden Ladders.

(2) You must make sure portable ladders manufactured before January 1, 2006, meet the design and construction requirements and specifications of the appropriate ANSI standard in effect on the date of manufacture:

(a) ANSI A14.1, American National Standard for Ladders-Portable Wood-Safety Requirements.

(b) ANSI A14.2, American National Standard for Ladders-Portable Metal-Safety Requirements.

(c) ANSI A14.5, American National Standard for Ladders-Portable Reinforced Plastic-Safety Requirements.

Note: | A commercially manufactured portable ladder should have a label indicating it meets the requirements of the ANSI standard. If in doubt, check with the manufacturer. |

PDF296-876-300

Ladder care.

Summary

Your responsibility: To make sure portable ladders are inspected, maintained, stored, and transported properly.

You must meet the requirements... | in this section: |

Condition and inspection | WAC 296-876-30005 |

Repair | WAC 296-876-30010 |

Storage | WAC 296-876-30015 |

Transport | WAC 296-876-30020 |

PDF296-876-30005

Condition and inspection.

(1) You must keep portable ladders in good, usable condition. Good, usable condition includes, but is not limited to:

(a) Joints between the steps or rungs and the side rails are tight.

(b) Rungs, cleats, or steps are not bent, broken, or missing.

(c) Side rails are not bent, broken, or split.

(d) All bolts and rivets are in place and secure.

(e) Hardware, fittings, and accessories are securely attached and working properly.

(f) Ropes are not frayed or badly worn.

(g) Moveable parts operate freely without binding or excessive play.

(h) Safety feet and other auxiliary equipment are not excessively worn.

(i) Metal components are not corroded.

(j) There are no other faulty or defective components.

(k) Rungs and steps of portable metal ladders are corrugated, knurled, dimpled, coated with skid-resistant material, or otherwise treated to minimize the possibility of slipping.

(l) Each stepladder or combination ladder used in a stepladder mode is equipped with a metal spreader or locking device that securely holds the front and back sections in an open position while the ladder is in use.

(m) You must maintain portable ladder surfaces free of puncture and laceration hazards.

(n) You must ensure portable ladder rungs, steps, and cleats are parallel, level, and uniformly spaced when the ladder is in position for use.

(2) You must make sure wood ladders are not coated with an opaque covering except for the minimum amount necessary for identification and warning information which may be placed on one face only of a side rail.

(3) You must have employees inspect portable ladders, as follows:

(a) Competent person when required by Table 1, Ladder Inspection Criteria; and

(b) Trained ladder user, prior to the user's initial use in each shift, and as necessary during the use to identify defects or damage that may occur during a work shift after the initial check. For example, if a ladder tips over, falls off a structure (e.g., roof) or vehicle, is struck by an object (e.g., vehicle or machine), or used in a corrosive environment, evidence of this damage would necessitate the authorized ladder user to initiate a ladder competent person inspection to determine whether the ladder is still safe to use.

(4) You must make sure any ladder with structural damage or other hazardous defect is:

(a) Marked to identify it as defective or tagged with "do not use" or similar language; and

(b) Removed from service.

Note: | Ladders subjected to certain acids or alkali materials may experience chemical corrosion and a reduction in strength. Consult the manufacturer or a qualified person prior to use. |

Table 1

Ladder Inspection Criteria

When the ladder is: | Do the following: | |

First placed into service as necessary while in service | Inspect the ladder for visible defects, including, but not limited to: | |

1. | Working parts; and | |

2. | Rung or step connections to the side rails. | |

Damaged by impact or tips over | 1. | Visually inspect the ladder for dents, bends, cracks or splits |

2. | Check: | |

a. | Rung or step connections to the side rails. | |

b. | Hardware connections. | |

c. | Rivets for shear damage. | |

d. | All other components. | |

Exposed to excessive heat such as a fire | 1. | Visually inspect the ladder for damage. |

2. | Test for deflection and strength characteristics using the "in-service use tests" contained in the appropriate ANSI. | |

EXEMPTION: Job-made wooden ladders are not to be subjected to load or impact tests. Those tests may weaken lumber components or fasteners, causing hidden damage that could result in sudden failure during use. | ||

(5) You must ensure stepstools have a minimum clear width of ten and one-half inches (26.7 cm).

(6) You must ensure portable ladder rungs, steps, and cleats have a minimum clear width of eleven and one-half inches (29 cm).

EXEMPTION: | The minimum clear width does not apply to ladders with narrow rungs that are not designed to be stepped on, such as those located on the tapered end of orchard ladders and similar ladders. |

[Statutory Authority: RCW 49.17.010, 49.17.040, 49.17.050, 49.17.060 and chapter 49.17 RCW. WSR 20-09-146, § 296-876-30005, filed 4/21/20, effective 10/1/20; WSR 14-09-095, § 296-876-30005, filed 4/22/14, effective 7/1/14. Statutory Authority: RCW 49.17.010, 49.17.040, 49.17.050, 49.17.060. WSR 05-20-068, § 296-876-30005, filed 10/4/05, effective 1/1/06.]

PDF296-876-30010

Repair.

(1) You must make sure repairs restore the ladder to a condition meeting its original design criteria.

(2) You must prohibit repairs to a defective side rail.

Note: | A commercially manufactured ladder with a defective side rail cannot be repaired by the user. Side rail repair can only be done by the manufacturer. |

PDF296-876-30015

Storage.

You must make sure material is not put on ladders in storage.

Note: | Store portable ladders on racks designed to protect them when not in use. The racks should have enough supporting points to prevent the ladder from sagging. Do not store wood ladders near sources of heat, moisture, or dampness. |

PDF296-876-30020

Transport.

(1) You must properly support ladders while transporting them on vehicles.

(2) You must make sure ladders transported in a truck rack are positively secured in a fixed position that prevents chafing or abrasion.

Note: | Securing the ladder to each support point will greatly reduce damage due to road shock. |

PDF296-876-400

Portable ladder use.

Summary

Your responsibility: To use portable ladders safely.

You must meet the requirements... | in this section: |

Designed use | WAC 296-876-40005 |

Workplace activities or traffic | WAC 296-876-40010 |

Support | WAC 296-876-40015 |

Set-up | WAC 296-876-40020 |

Climbing and descending | WAC 296-876-40025 |

Getting on and off ladders at upper levels | WAC 296-876-40030 |

Exposed electrical hazards | WAC 296-876-40035 |

Persons on ladders | WAC 296-876-40040 |

Multisection ladders | WAC 296-876-40045 |

Self-supporting ladders | WAC 296-876-40050 |

PDF296-876-40005

Designed use.

(1) You must use ladders only for their intended purpose.

Note: | Unless specifically recommended by the manufacturer, do not use a ladder as a: |

1. Brace. | |

2. Skid. | |

3. Lever. | |

4. Guy or gin pole. | |

5. Gangway. | |

6. Platform. | |

7. Scaffold plank. | |

8. Material hoist. |

(2) You must make sure not to overload ladders. Do not exceed either the:

(a) Maximum intended load; or

(b) Manufacturer's rated capacity.

PDF296-876-40010

Workplace activities or traffic.

(1) You must protect ladders that are set up in a location where they could be displaced by workplace activities or traffic by either:

(a) Securing the ladder to prevent accidental displacement; or

(b) Using a barricade to keep the activities or traffic away from the ladder.

(2) You must protect ladders that are set-up in front of doors that open towards the ladder by doing at least one of the following:

(a) Block the door open.

(b) Lock the door.

(c) Guard the door to keep it from opening into the ladder.

PDF296-876-40015

Support.

(1) You must place the ladder either:

(a) With a secure footing on a firm, level support surface; or

(b) Secure the ladder to prevent accidental displacement.

(2) You must make sure a ladder is not placed on ice, snow, or other slippery surface unless the ladder is prevented from accidental displacement by either:

(a) Securing it; or

(b) Providing the ladder with slip-resistant feet.

Note: | Slip-resistant feet are not a substitute for care in placing, lashing, or holding a ladder that is used on a slippery surface. |

(3) You must make sure ladders are not placed on boxes, barrels, or other unstable bases to obtain additional height.

(4) You must place a straight ladder so the side rails are equally supported by the top support, unless the ladder is equipped with a single support attachment.

(5) You must make sure the top support of the ladder is reasonably rigid and able to support the load.

PDF296-876-40020

Set-up.

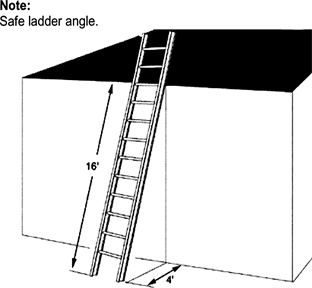

(1) You must set up nonself-supporting ladders at a safe angle. The ladder is set at the proper angle when the horizontal distance from the top support to the foot of the ladder is approximately one-quarter the working length of the ladder.

(2) You must set up job-made ladders with spliced side rails so that the horizontal distance from the top support to the foot of the ladder is not greater than one-eighth the working length of the ladder.

(3) You must set up the top of a nonself-supporting ladder so that both side rails are supported, unless the ladder is equipped with a single support attachment.

|

[Statutory Authority: RCW 49.17.010, 49.17.040, 49.17.050, 49.17.060 and chapter 49.17 RCW. WSR 20-09-146, § 296-876-40020, filed 4/21/20, effective 10/1/20; WSR 14-09-095, § 296-876-40020, filed 4/22/14, effective 7/1/14. Statutory Authority: RCW 49.17.010, 49.17.040, 49.17.050, 49.17.060. WSR 05-20-068, § 296-876-40020, filed 10/4/05, effective 1/1/06.]

PDF296-876-40025

Climbing and descending.

(1) You must have employees use at least one hand to grasp the ladder when climbing up and down it.

(2) You must face the ladder when climbing or descending.

(3) You must keep ladders free of oil, grease, or other slippery materials.

(4) You must keep the area around the top and bottom of ladders clear.

(5) You must make sure single-rail ladders are not used.

(6) You must make sure no employee carries any object or load that could cause the employee to lose balance and fall while climbing up or down the ladder.

[Statutory Authority: RCW 49.17.010, 49.17.040, 49.17.050, 49.17.060 and chapter 49.17 RCW. WSR 20-09-146, § 296-876-40025, filed 4/21/20, effective 10/1/20; WSR 14-09-095, § 296-876-40025, filed 4/22/14, effective 7/1/14. Statutory Authority: RCW 49.17.010, 49.17.040, 49.17.050, 49.17.060. WSR 05-20-068, § 296-876-40025, filed 10/4/05, effective 1/1/06.]

PDF296-876-40030

Getting on and off ladders at upper levels.

(1) You must make sure a ladder used to access an upper level has the side rails extended at least three feet (0.9 m) above the landing surface if the ladder length permits.

(2) You must do the following if a ladder used to access an upper level is not long enough to obtain a three-foot side rail extension above the landing surface:

(a) Secure the ladder at the top to a rigid support that will not deflect.

(b) Provide a grasping device, such as a grabrail, to assist in mounting and dismounting the ladder.

(c) Make sure the ladder deflection under a load would not, by itself, cause it to slip off its support.

(3) You must make sure, if two or more separate ladders are used to reach an elevated work area, that the ladders are offset with a platform or landing between them.

EXEMPTION: | A platform or landing is not required when a portable ladder is used to reach a fixed ladder on structures such as utility towers and billboards where the bottom of the fixed ladder is elevated to limit access. |

PDF296-876-40035

Exposed electrical hazards.

You must use ladders with nonconductive side rails where the ladder could contact uninsulated, energized electric lines or equipment. Metal ladders or other ladders specifically designed to permit grounding or dissipation of static electricity may be used around high-static electrical fields if all of the following are met:

(1) Using nonconductive ladders would present a greater hazard than using conductive ladders.

(2) Ladders are prominently marked and identified as being conductive.

(3) Ladders are grounded when used near energized lines or equipment.

Note: | Examples of ladders with conductive side rails are metal ladders, and wood or reinforced plastic ladders with metal side rail reinforcement. |

PDF296-876-40040

Persons on ladders.

(1) You must make sure a ladder is not moved, shifted, or adjusted while anyone is on it.

(2) You must secure the ladder at the top and bottom when working from it.

(3) You must use a safety belt with a lanyard that is secured to the ladder when doing any work that:

(a) Requires the use of both hands; and

(b) Is done from a ladder more than twenty-five feet above the ground or floor.

(4) You must prohibit work being done from a ladder more than twenty-five feet above the ground or floor if the work requires wearing eye protection or a respirator.

PDF296-876-40045

Multisection ladders.

(1) You must make sure not to tie or fasten ladder sections together to make longer ladders unless:

(a) The ladder manufacturer endorses this type of use; and

(b) You have hardware fittings specifically designed for this purpose.

(2) You must make sure each section of a multisection ladder, when fully extended and locked in position to be used, overlaps the adjacent section as indicated in Table 2, Minimum Required Overlap for Extension Ladders.

Table 2

Minimum Required Overlap for Extension Ladders

If the ladder size (feet) is: | Minimum required overlap (feet) for a two-section ladder is: |

Up to and including 36 | 3 |

Over 36 up to and including 48 | 4 |

Over 48 up to and including 60 | 5 |

PDF296-876-40050

Self-supporting ladders.

(1) You must make sure self-supporting ladders are not used as single ladders or in the partially closed position.

(2) You must make sure stepladders are fully opened with the spreaders locked.

(3) You must make sure not to climb on the rear braces of a self-supporting ladder unless they are designed and recommended for that purpose by the manufacturer.

(4) You must prohibit standing or stepping on the:

(a) Top cap and top step of a step or trestle ladder.

(b) Bucket or pail shelf of a self-supporting ladder.

EXEMPTION: | The restriction against using the top step is not applicable if it is eighteen inches or more below the top cap. |

PDF296-876-500

Fixed ladder design and construction installed on or after December 1, 2006.

Summary

Your responsibility: To make sure fixed ladders installed on or after December 1, 2006, meet design and construction requirements.

You must meet the requirements... | in this section: |

Design and construction—Fixed ladders installed on or after December 1, 2006 | WAC 296-876-50010 |

[Statutory Authority: RCW 49.17.010, 49.17.040, 49.17.050, 49.17.060, and chapter 49.17 RCW. WSR 14-09-095, § 296-876-500, filed 4/22/14, effective 7/1/14. Statutory Authority: RCW 49.17.010, 49.17.040, 49.17.050, 49.17.060. WSR 06-16-020, § 296-876-500, filed 7/24/06, effective 12/1/06; WSR 05-20-068, § 296-876-500, filed 10/4/05, effective 1/1/06.]

PDF296-876-50010

Design and construction—Fixed ladders installed on or after December 1, 2006.

You must make sure fixed ladders installed on or after December 1, 2006, meet the design and construction requirements of ANSI A14.3-2002, American National Standard for Ladders-Fixed-Safety Requirements.

Note: | Ladders will be considered to have met the requirements of this section if they meet the design and construction requirements of ANSI A14.3, American National Standard for Ladders-Fixed-Safety Requirements, in effect at the time they are installed. |

PDF296-876-600

Fixed ladder design and construction installed before December 1, 2006.

Summary

Your responsibility: To make sure fixed ladders installed before December 1, 2006, meet design and construction requirements.

You must meet the requirements... | in this section: |

Design and construction—Fixed ladders installed before December 1, 2006. | WAC 296-876-60005 |

Design loads | WAC 296-876-60010 |

Pitch | WAC 296-876-60015 |

Welding | WAC 296-876-60020 |

Ladder surfaces | WAC 296-876-60025 |

Rungs, cleats and steps | WAC 296-876-60030 |

Side rails | WAC 296-876-60035 |

Clearances | WAC 296-876-60040 |

Step-across distance | WAC 296-876-60045 |

Extensions and grab bars | WAC 296-876-60050 |

Hatches | WAC 296-876-60055 |

Platforms | WAC 296-876-60060 |

Protective structures and equipment | WAC 296-876-60065 |

Cages | WAC 296-876-60070 |

Wells | WAC 296-876-60075 |

Ladder safety devices | WAC 296-876-60080 |

[Statutory Authority: RCW 49.17.010, 49.17.040, 49.17.050, 49.17.060, and chapter 49.17 RCW. WSR 14-09-095, § 296-876-600, filed 4/22/14, effective 7/1/14. Statutory Authority: RCW 49.17.010, 49.17.040, 49.17.050, 49.17.060. WSR 06-16-020, § 296-876-600, filed 7/24/06, effective 12/1/06; WSR 05-20-068, § 296-876-600, filed 10/4/05, effective 1/1/06.]

PDF296-876-60005

Design and construction—Fixed ladders installed before December 1, 2006.

You must make sure fixed ladders installed before December 1, 2006, meet the requirements of WAC 296-876-60010 through 296-876-60080.

Note: | Ladders will be considered to have met the requirements of this section if they meet the design and construction requirements of ANSI A14.3, American National Standard for Ladders-Fixed-Safety Requirements, in effect at the time they are installed. |

PDF296-876-60010

Design loads.

(1) You must make sure each ladder is able to support, without failure, the total of the following loads:

(a) At least two loads of two hundred and fifty pounds each, concentrated between any two consecutive attachments.

(b) Any additional concentrated loads of two hundred and fifty pounds each determined from the anticipated use of the ladder.

(c) Anticipated loads caused by all of the following that apply:

(i) Ice buildup.

(ii) Winds.

(iii) Rigging attached to the ladder, including the load to be lifted.

(iv) Impact loads resulting from the use of ladder safety devices.

(2) You must make sure the design of rails, supports, and fastenings includes:

(a) Live loads to be supported by the ladder; and

(b) The weight of the ladder and everything attached to it.

(3) You must consider all live loads to be concentrated at the point or points that will cause the maximum stress on the ladder or structural member.

(4) You must make sure each step or rung is capable of supporting a single concentrated load of at least two hundred fifty pounds applied in the middle of the step or rung.

(5) You must make sure the design stresses for wood components of ladders meet the requirements and specifications of ANSI A14.1, American National Standard for Ladders-Portable Wood-Safety Requirements, in effect when the ladder was installed.

(6) You must make sure fastenings are designed to meet the ladder load requirements.

PDF296-876-60015

Pitch.

You must make sure the pitch of the ladder is no greater than ninety degrees from the horizontal.

Notes: | 1. The preferred pitch of fixed ladders is within the range of seventy-five to ninety degrees from the horizontal. Ladders with a pitch range of sixty to seventy-five degrees from the horizontal are considered substandard and are only permitted if necessary to meet the installation requirements. |

2. Fixed stairs are an alternative for installations where a pitch angle of less than sixty degrees is necessary. See Fixed industrial stairs, WAC 296-24-765, in the General Safety and Health Standards, chapter 296-24 WAC. |

PDF296-876-60020

Welding.

You must make sure welding meets the requirements of the ANSI A14.3, American National Standard for Ladders-Fixed-Safety Requirements, in effect at the time the ladder was installed.

PDF296-876-60025

Ladder surfaces.

See the fixed ladder inspection requirements under WAC 296-876-70010 Inspection and repair.

[Statutory Authority: RCW 49.17.010, 49.17.040, 49.17.050, 49.17.060 and chapter 49.17 RCW. WSR 20-09-146, § 296-876-60025, filed 4/21/20, effective 10/1/20; WSR 14-09-095, § 296-876-60025, filed 4/22/14, effective 7/1/14. Statutory Authority: RCW 49.17.010, 49.17.040, 49.17.050, 49.17.060. WSR 06-16-020, § 296-876-60025, filed 7/24/06, effective 12/1/06.]

PDF296-876-60030

Rungs, cleats and steps.

(1) You must make sure rungs have a minimum diameter as follows:

(a) Rungs of wood ladders are at least one and one-eighth inches.

(b) Rungs of metal ladders subject to unusually corrosive exposures, such as individual metal rungs imbedded in concrete which serve as access to pits and to other areas under floors, are at least one inch.

(c) Rungs of all other metal ladders are at least three-quarters inch.

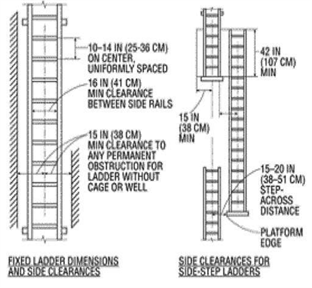

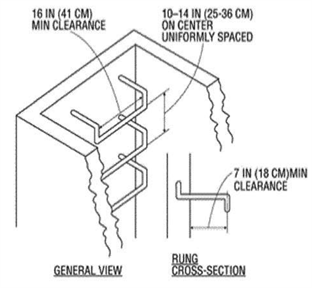

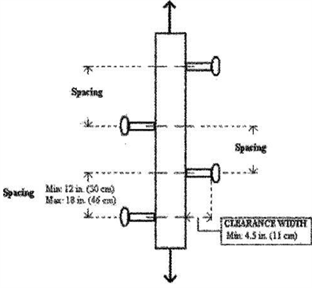

(2) You must make sure rungs, cleats, and steps are spaced so the distance from the centerline of one rung to the centerline of the next rung does not exceed fourteen inches, or is less than ten inches (see Figure D-2 in this section). Ladder rungs in elevator shafts must be spaced not less than six inches (15 cm) apart, and not more than sixteen and one-half inches (42 cm) apart, as measured rung from rung centerline to the next centerline (along the ladder side rails).

(3) You must make sure the minimum inside clear width of the stepping surface of rungs, steps, or cleats is sixteen inches (see Figure D-2 below).

|

Figure D-2 - Side-Step Fixed Ladder Sections

(4) You must make sure individual rung or step-type ladders have rungs or steps that are shaped so that a person's foot cannot slide off the end (see Figure D-4 below).

|

Figure D-4 - Individual Rung Ladder

[Statutory Authority: RCW 49.17.010, 49.17.040, 49.17.050, 49.17.060 and chapter 49.17 RCW. WSR 20-09-146, § 296-876-60030, filed 4/21/20, effective 10/1/20; WSR 14-09-095, § 296-876-60030, filed 4/22/14, effective 7/1/14. Statutory Authority: RCW 49.17.010, 49.17.040, 49.17.050, 49.17.060. WSR 06-16-020, § 296-876-60030, filed 7/24/06, effective 12/1/06.]

PDF296-876-60035

Side rails.

(1) You must make sure the shape of the side rail:

(a) Provides an adequate gripping surface; and

(b) Is uniform throughout the length of climb.

(2) You must make sure a side rail that has been spliced to obtain a longer length is at least equivalent in strength to a one-piece side rail made of the same material.

PDF296-876-60040

Clearances.

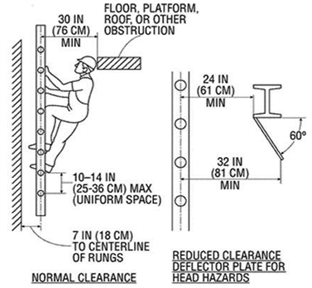

(1) You must make sure ladders without wells or cages are at least thirty inches from the nearest permanent object on the climbing side, measured perpendicular to the ladder from the centerline of the rungs, cleats, or steps.

EXEMPTION: | When unavoidable obstructions are encountered, the minimum perpendicular clearance between the centerline of the rungs, cleats, or steps and an obstruction on the climbing side may be reduced to twenty-four inches if a deflection device is installed to guide persons around the obstruction. |

(2) You must make sure ladders without wells or cages have a clear width from the nearest permanent object on each side of the ladder of at least fifteen inches, measured from the center of the rungs, cleats, or steps.

(3) You must make sure the distance from the centerline of the rungs, cleats, or steps to the nearest permanent object in back of the ladder is at least seven inches.

EXEMPTION: | Fixed ladders in elevator pits may reduce the minimum clearance from the ladder to the nearest permanent object in back of the ladder to four and one-half inches. |

|

Figure D-5 - Fixed Ladder Clearances

[Statutory Authority: RCW 49.17.010, 49.17.040, 49.17.050, 49.17.060 and chapter 49.17 RCW. WSR 20-09-146, § 296-876-60040, filed 4/21/20, effective 10/1/20; WSR 14-09-095, § 296-876-60040, filed 4/22/14, effective 7/1/14. Statutory Authority: RCW 49.17.010, 49.17.040, 49.17.050, 49.17.060. WSR 06-16-020, § 296-876-60040, filed 7/24/06, effective 12/1/06.]

PDF296-876-60045

Step-across distance.

(1) You must make sure a through ladder at the point of access or egress has a step-across distance, measured from the centerline of the steps or rungs to the nearest edge of the landing area, that is:

(a) Not less than seven inches; or

(b) Greater than twelve inches.

(2) You must make sure a side-step ladder at the point of access or egress has a step-across distance, measured from the centerline of the ladder to the nearest edge of the access point(s) of the landing area or platform, that is:

(a) Not less than fifteen inches; or

(b) Greater than twenty inches.

[Statutory Authority: RCW 49.17.010, 49.17.040, 49.17.050, 49.17.060 and chapter 49.17 RCW. WSR 20-09-146, § 296-876-60045, filed 4/21/20, effective 10/1/20; WSR 14-09-095, § 296-876-60045, filed 4/22/14, effective 7/1/14. Statutory Authority: RCW 49.17.010, 49.17.040, 49.17.050, 49.17.060. WSR 06-16-020, § 296-876-60045, filed 7/24/06, effective 12/1/06.]

PDF296-876-60050

Extensions and grab bars.

(1) You must make sure the side rails of through or side-step ladders extend forty-two inches above the top of the access level or landing platform.

Note: | For a parapet ladder, the access level is: |

1. The roof if the parapet is cut to permit passage through it; or | |

2. The top of the parapet if it is continuous and uncut. |

(2) You must make sure the extension of a through ladder above the access level or landing platform has:

(a) Steps or rungs omitted from the extension; and

(b) Clearance between the side rails that is:

(i) Not less than twenty-four inches; or

(ii) Greater than thirty inches.

EXEMPTION: | The maximum clearance between side rails of the extension may be increased to thirty-six inches if the ladder has a ladder safety device. |

(3) You must make sure side-step ladders have the steps or rungs and the side rails continuous in the extension (see Figure D-2 in WAC 296-876-60030).

(4) You must make sure individual rung-step ladders are extended at least forty-two inches above the access level or landing platform by:

(a) Continuing the rung spacings as horizontal grab bars; or

(b) Providing vertical grab bars that have the same lateral spacing as the vertical legs of the rungs.

EXEMPTION: | Extensions are not required for individual rung-step ladders with access openings through a manhole or hatch. |

(5) You must make sure grab bars:

(a) Are at least four inches from the nearest permanent object in back of the grab bar, measured from the centerline of the grab bar;

(b) Do not extend beyond the rungs on the climbing side of the ladder; and

(c) The minimum size (cross-section) of grab bars is the same size as the rungs of the ladder.

EXEMPTION: | WAC 296-876-60050 (5)(c) applies to general industry only. See the exemption list in the scope section of WAC 296-876-100 for more information. |

[Statutory Authority: RCW 49.17.010, 49.17.040, 49.17.050, 49.17.060 and chapter 49.17 RCW. WSR 20-09-146, § 296-876-60050, filed 4/21/20, effective 10/1/20. Statutory Authority: RCW 49.17.010, 49.17.040, 49.17.050, and 49.17.060. WSR 16-23-141, § 296-876-60050, filed 11/22/16, effective 12/23/16. Statutory Authority: RCW 49.17.010, 49.17.040, 49.17.050, 49.17.060, and chapter 49.17 RCW. WSR 14-09-095, § 296-876-60050, filed 4/22/14, effective 7/1/14. Statutory Authority: RCW 49.17.010, 49.17.040, 49.17.050, 49.17.060. WSR 06-16-020, § 296-876-60050, filed 7/24/06, effective 12/1/06.]

PDF296-876-60055

Hatches.

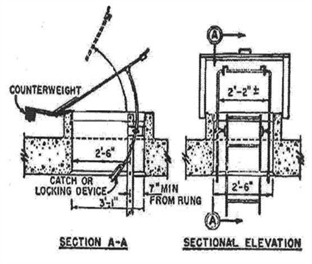

When a fixed ladder terminates at a hatch (see Figure D-3 below), you must ensure the hatch cover:

(1) Opens with sufficient clearance to provide easy access to or from the ladder.

EXEMPTION: | WAC 296-875-60055(1) applies to general industry only. See the exemption list in the scope of WAC 296-876-100 for more information. |

(2) Opens at least seventy degrees from the horizontal if the hatch is counterbalanced.

(3) You must make sure the inside clear width of the hatch is a nominal thirty inches.

(4) You must make sure the distance from the centerline of the rungs or cleats to the edge of the hatch opening on the climbing side, measured perpendicular to the ladder, is:

(a) Not less than twenty-four inches; or

(b) Greater than thirty inches.

(5) You must make sure hatches with clearance on the climbing side of the ladder that is between twenty-four and twenty-seven inches are fitted with a deflector plate mounted at an angle of sixty degrees from the horizontal.

Note: | The springs or other counterbalance mechanisms for the hatch may project into the hatch opening provided they do not reduce clearance to less than twenty-four inches and a deflector plate is installed to guide persons around the obstruction. |

|

Figure D-3 - Example of Counterbalanced Hatch Cover at Roof

[Statutory Authority: RCW 49.17.010, 49.17.040, 49.17.050, 49.17.060 and chapter 49.17 RCW. WSR 20-09-146, § 296-876-60055, filed 4/21/20, effective 10/1/20; WSR 14-09-095, § 296-876-60055, filed 4/22/14, effective 7/1/14. Statutory Authority: RCW 49.17.010, 49.17.040, 49.17.050, 49.17.060. WSR 06-16-020, § 296-876-60055, filed 7/24/06, effective 12/1/06.]

PDF296-876-60060

Platforms.

(1) You must make sure landing platforms for side-step ladders extend at least thirty inches on the climbing side of the ladder.

(2) You must make sure landing platforms are:

(a) At least thirty inches wide; and

(b) Equipped with standard railings and toeboards placed to allow safe access to the ladder.

Reference: | Requirements for standard railings and toeboards are in Railing, toeboards, and cover specifications, WAC 296-24-75011, the General Safety and Health Standards, chapter 296-24 WAC. |

(3) You must make sure the top rung or step of the ladder is level with the landing served by the ladder.

(4) You must make sure the spacing from the landing platform to the first rung below the platform of a through ladder is the same as the rung spacing of the ladder.

(5) You must make sure, if two or more separate ladders are used to reach an elevated work area, that the ladders are offset with a platform or landing between them.

EXEMPTION: | A platform or landing is not required when a portable ladder is used to reach a fixed ladder on structures such as utility towers and billboards where the bottom of the fixed ladder is elevated to limit access. |

PDF296-876-60065

Protective structures and equipment.

Note: | DOSH and federal OSHA plan to phase out the recognition of ladder cages as effective means of fall-protection in the requirements below. New fixed ladders constructed after October 1, 2020, must incorporate ladder safety systems. Employers have until October 1, 2040, to equip preexisting fixed ladders with ladder safety systems/personal fall arrest systems. |

(1) You must make sure a cage, well, or ladder safety system is provided if:

(a) The length of climb is less than twenty-four feet; and

(b) The top of the ladder is more than twenty-four feet above the ground, floor, or roof.

(2) You must make sure a ladder with a single length of climb that is equal to or greater than twenty-four feet is either:

(a) Equipped with a ladder safety device; or

(b) Uses multiple ladder sections and meets all of the following:

(i) Each section is provided with a cage or well.

(ii) The length of climb of any ladder section is not greater than fifty feet.

(iii) Each ladder section is offset from adjacent sections.

(iv) Landing platforms are provided at maximum intervals of fifty feet.

EXEMPTION: | During construction activities, a self-retracting lifeline with landing platforms provided at maximum intervals of one hundred fifty feet may be used instead of a ladder safety device or multiple ladder sections. |

[Statutory Authority: RCW 49.17.010, 49.17.040, 49.17.050, 49.17.060 and chapter 49.17 RCW. WSR 20-09-146, § 296-876-60065, filed 4/21/20, effective 10/1/20; WSR 14-09-095, § 296-876-60065, filed 4/22/14, effective 7/1/14. Statutory Authority: RCW 49.17.010, 49.17.040, 49.17.050, 49.17.060. WSR 06-16-020, § 296-876-60065, filed 7/24/06, effective 12/1/06.]

PDF296-876-60070

Cages.

(1) You must make sure the cage meets all of the following:

(a) Extends at least forty-two inches above the top of the platform or above the point of access and egress at the top of the ladder.

(b) Has provisions for accessing and egressing the platform or the point of access or egress of the ladder.

(c) There is at least twenty-seven inches, but not more than thirty inches, from the cage to the centerline of the step or rung at all points except where the cage flares at the bottom of the ladder.

(d) The cage is at least twenty-seven inches wide.

(e) There are no projections inside the cage.

(2) You must make sure the bottom of the cage is:

(a) At least seven feet but not more than eight feet above the point of access to the bottom of the ladder; and

(b) Flared at least four inches all around within the distance between the bottom horizontal band and the next higher band.

(3) You must make sure vertical bars are:

(a) Spaced at intervals of nine and one-half inches or less on center around the circumference of the cage; and

(b) Fastened to the inside of the horizontal bands.

(4) You must make sure the horizontal bands meet all of the following:

(a) The vertical intervals between horizontal bands are not more than four feet on center.

(b) The horizontal bands of ladders with side rails are fastened to the side rails.

(c) The horizontal bands of individual-rung ladders are fastened directly to the structure, building, or equipment.

PDF296-876-60075

Wells.

(1) You must make sure there is at least twenty-seven inches, but not more than thirty inches, from the centerline of the step or rung to the inside face of the well on the climbing side of the ladder.

(2) You must make sure the inside clear width is at least thirty inches.

(3) You must make sure the well:

(a) Completely encircles the ladder; and

(b) Is free of projections.

(4) You must make sure the bottom of the wall on the access side is at least seven feet, but not more than eight feet, above the point of access to the bottom of the ladder.

PDF296-876-60080

Ladder safety devices.

Notes: | • Requirements for ladder safety devices, also referred to as ladder safety systems, are described below. Ladder safety devices typically consist of a carrier (see definitions in WAC 296-876-099), safety sleeve or carrier/cable/rope grab, lanyard, connectors, and full body harness (typically with frontal d-ring). The requirements below apply to the combination of components in use. |

• Where an employer elects to use automatic self-retracting lifelines (SRL); and the SRL is installed, used, inspected, and maintained consistent with the manufacturer's instructions and terms of use, the SRL would fulfill the employer's ladder safety device obligations. | |

• Information related to fall protection requirements (fall arrest requirements, inspection criteria, training requirements, etc.) are found in DOSH's Safety Standards for Fall Protection (chapter 296-880 WAC). |

(1) You must make sure ladder safety devices and related support systems meet all of the following:

(a) Are capable of withstanding, without failure, the test drop of a five-hundred-pound weight for a free-fall distance of eighteen inches.

(b) The device does not require a person to continually hold, push, or pull any part of the device and allows them to have both hands free to grip the ladder.

(c) In the event of a fall, the device:

(i) Is activated within two feet; and

(ii) Limits the fall velocity to seven feet per second or less.

(d) Uses a connection between the carrier or lifeline and the point of attachment on the full body harness that is not longer than nine inches.

(2) You must make sure ladder safety devices with rigid carriers have mountings that:

(a) Are attached at each end of the carrier; and

(b) Have intermediate mountings that are all of the following:

(i) Spaced along the entire length of the carrier in accordance with the manufacturer's recommendations.

(ii) Installed within one foot below each splice on the carrier.

(iii) Have a maximum distance between mountings that is twenty-five feet or less.

(3) You must make sure ladder safety devices with flexible carriers have:

(a) Mountings that are attached at each end of the carrier; and

(b) Cable guides that are spaced at least twenty-five feet, but no further than forty feet, apart along the entire length of the carrier.

(4) You must make sure the design and installation of mountings and cable guides does not reduce the design strength of the ladder.

[Statutory Authority: RCW 49.17.010, 49.17.040, 49.17.050, 49.17.060 and chapter 49.17 RCW. WSR 20-09-146, § 296-876-60080, filed 4/21/20, effective 10/1/20; WSR 14-09-095, § 296-876-60080, filed 4/22/14, effective 7/1/14. Statutory Authority: RCW 49.17.010, 49.17.040, 49.17.050, 49.17.060. WSR 06-16-020, § 296-876-60080, filed 7/24/06, effective 12/1/06.]

PDF296-876-700

Fixed ladders inspection and maintenance.

Summary

Your responsibility: To make sure fixed ladders are inspected and maintained properly.

You must meet the requirements... | in this section: |

Protection against corrosion and deterioration | WAC 296-876-70005 |

Inspection and repair | WAC 296-876-70010 |

PDF296-876-70005

Protection against corrosion and deterioration.

(1) You must paint or otherwise treat metal ladders or metal parts to resist rust and corrosion if they are:

(a) Exposed to the elements; or

(b) Located where rust or corrosion could be expected.

(2) You must treat wood ladders used in conditions where decay may occur with a nonirritating preservative.

(3) You must make sure wood ladders are not coated with an opaque covering except for the minimum amount necessary for identification and warning information which may be placed on one face only of a side rail.

(4) You must treat the interface between different materials or use other means to prevent:

(a) One material from damaging or having a harmful effect on another material; and

(b) Electrolytic action between dissimilar metals.

PDF296-876-70010

Inspection and repair.

(1) You must keep ladders in safe condition.

(2) You must have employees inspect fixed ladders for visual defects, as follows:

(a) Competent person, when required by Table 1 (see WAC 296-876-30005), Ladder inspection criteria.

(b) Trained ladder user, prior to the user's initial use in each shift, and as necessary during the use to identify defects or damage that may occur during a work shift after the initial check. For example, if a ladder tips over, falls off a structure (e.g., roof) or vehicle, is struck by an object (e.g., vehicle or machine), or used in a corrosive environment, evidence of this damage would necessitate the authorized ladder user to initiate a ladder competent person inspection to determine whether the ladder is still safe to use.

EXEMPTION: | WAC 296-876-70010 (2)(c) applies to general industry only. See the exemption list in the scope section of this chapter (WAC 296-876-100) for more information. |

(3) You must make sure any ladder with structural damage or other hazardous defect is immediately removed from service.

Notes: | 1. Structural damage includes, but is not limited to, any of the following: |

a. Broken or missing rungs, cleats, or steps. | |

b. Broken or split rails. | |

c. Corroded components. | |

d. Bolts and welds missing or not secure. | |

2. A ladder is considered to be removed from service if any of the following are done: | |

a. It is marked to identify it as defective. | |

b. It is tagged with "do not use" or similar language. | |

c. It is blocked so that it cannot be used, for example, by using a plywood attachment that spans several rungs. |

(4) You must make sure repairs restore the ladder to a condition meeting its original design criteria.

(5) You must ensure wooden fixed ladders are not coated with any material that may obscure structural defects.

(6) You must maintain fixed ladder parts and surfaces free of splinters, sharp edges, burrs, projections, puncture, and laceration hazards that may be hazardous to persons using the ladder.

(7) You must ensure fixed ladders are capable of supporting their maximum intended load.

(8) You must ensure fixed ladder rungs, steps, and cleats are parallel, level, and uniformly spaced.

[Statutory Authority: RCW 49.17.010, 49.17.040, 49.17.050, 49.17.060 and chapter 49.17 RCW. WSR 20-09-146, § 296-876-70010, filed 4/21/20, effective 10/1/20; WSR 14-09-095, § 296-876-70010, filed 4/22/14, effective 7/1/14. Statutory Authority: RCW 49.17.010, 49.17.040, 49.17.050, 49.17.060. WSR 06-16-020, § 296-876-70010, filed 7/24/06, effective 12/1/06.]

PDF296-876-800

Fixed ladder use.

Summary

Your responsibility: To use fixed ladders safely.

You must meet the requirements... | in this section: |

Design load | WAC 296-876-80005 |

Climbing and descending | WAC 296-876-80010 |

PDF296-876-80005

Designed load.

You must make sure not to overload ladders. Do not exceed either the:

(1) Maximum intended load; or

(2) Manufacturer's rated capacity.

PDF296-876-80010

Climbing and descending.

(1) You must have employees use at least one hand to grasp the ladder when climbing up and down it.

(2) You must face the ladder when climbing or descending.

(3) You must keep ladders free of oil, grease, or other slippery materials.

(4) You must make sure no employee carries any object or load that could cause the employee to lose balance and fall while climbing up or down the ladder.

(5) You must make sure fixed ladders are used only for the purposes for which they were designed.

[Statutory Authority: RCW 49.17.010, 49.17.040, 49.17.050, 49.17.060 and chapter 49.17 RCW. WSR 20-09-146, § 296-876-80010, filed 4/21/20, effective 10/1/20; WSR 14-09-095, § 296-876-80010, filed 4/22/14, effective 7/1/14. Statutory Authority: RCW 49.17.010, 49.17.040, 49.17.050, 49.17.060. WSR 06-16-020, § 296-876-80010, filed 7/24/06, effective 12/1/06.]

PDF296-876-90005

Step bolt requirements.

In addition to the walking-working surface rule (WAC 296-24-73505) requirements, and the relevant fixed ladder standard requirements in this chapter, you must ensure:

(1) Each step bolt installed on or after October 1, 2020, in an environment where corrosion may occur is constructed of, or coated with, material that protects against corrosion.

(2) Each step bolt is designed, constructed, and maintained to prevent the employee's foot from slipping off the end, or side edge, of the step bolt.

(3) Step bolts are uniformly spaced at a vertical distance of not less than twelve inches (30 cm) and not more than eighteen inches (46 cm) apart, measured center to center (see Figure D-6 of this section). The spacing from the entry and exit surface to the first step bolt may differ from the spacing between the other step bolts.

(4) Each step bolt has a minimum clear width of four and one-half inches (11 cm).

(5) The minimum perpendicular distance between the centerline of each step bolt to the nearest permanent object in back of the step bolt is seven inches (18 cm). When the employer demonstrates that an obstruction cannot be avoided, the distance must be at least four and one-half inches (11 cm).

|

Figure D-6 - Step Bolt Spacing

(6) Each step bolt installed before October 1, 2020, is capable of supporting its maximum intended load.

(7) Each step bolt installed on or after October 1, 2020, is capable of supporting at least four times its maximum intended load.

(8) Each step bolt is inspected at the start of the work shift and maintained in accordance with the walking-working surface rule (WAC 296-24-73505).

(9) Each step bolt installed before October 1, 2020, is capable of supporting its maximum intended load.

(10) Each step bolt installed on or after October 1, 2020, is capable of supporting at least four times its maximum intended load.

(11) Each step bolt is inspected at the start of the work shift and maintained in accordance with the walking-working surface rule (WAC 296-24-73505).

PDF296-876-90010

Manhole step requirements.

In addition to the walking-working surface rule (WAC 296-24-73505) requirements and the relevant fixed ladder standard requirements (chapter 296-876 WAC), you must ensure:

(1) Each manhole step is capable of supporting its maximum intended load.

(2) Rungs and steps of manhole entry ladders that are supported by the manhole opening have a minimum clear width of nine inches (23 cm).

(3) Each manhole step installed on or after January 17, 2017:

(a) Has a corrugated, knurled, dimpled, or other surface that minimizes the possibility of an employee slipping.

(b) Is constructed of, or coated with, material that protects against corrosion if the manhole step is located in an environment where corrosion may occur.

(c) Has a minimum clear step width of ten inches (25 cm).

(d) Is uniformly spaced at a vertical distance not more than sixteen inches (41 cm) apart, measured center to center between steps. The spacing from the entry and exit surface to the first manhole step may differ from the spacing between the other steps.

(e) Has a minimum perpendicular distance between the centerline of the manhole step to the nearest permanent object in back of the step of at least four and one-half inches (11 cm).

(f) Is designed, constructed, and maintained to prevent the employee's foot from slipping or sliding off the end.

(4) The employer must ensure that each manhole step is inspected at the start of the work shift and maintained in accordance with the walking-working surface rule (WAC 296-24-73505).

PDF296-876-910

Mobile ladder stands and mobile ladder stand platforms.

Summary

Your responsibility: To meet these requirements for mobile ladder stands and mobile ladder stand platforms.

You must meet the requirements... | in this section: |

General requirements | WAC 296-876-91005 |

Design requirements for mobile ladder stands | WAC 296-876-91010 |

Design requirements for mobile ladder stand platforms | WAC 296-876-91015 |

PDF296-876-91005

General requirements.

You must ensure:

(1) Mobile ladder stands and platforms have a step width of at least sixteen inches (41 cm).

(2) Steps and platforms of mobile ladder stands and platforms are slip resistant. Slip-resistant surfaces must be either an integral part of the design and construction of the mobile ladder stand and platform, or provided as a secondary process or operation, such as dimpling, knurling, shotblasting, coating, spraying, or applying durable slip-resistant tapes.

(3) Mobile ladder stands and platforms are capable of supporting at least four times their maximum intended load.

(4) Load bearing wheels or casters are capable of supporting their proportional share of four times the maximum intended load, plus their proportional share of the unit's weight.

(5) Unless otherwise specified in this section, mobile ladder stands and platforms with a top step height of four feet (1.2 m) or above have handrails with a vertical height of twenty-nine and one-half inches (75 cm) to thirty-seven inches (94 cm), measured from the front edge of a step. Removable gates or nonrigid members, such as chains, may be used instead of handrails in special-use applications.

(6) The maximum work-surface height of mobile ladder stands and platforms does not exceed four times the shortest base dimension, without additional support. For greater heights, outriggers, counterweights, or comparable means that stabilize the mobile ladder stands and platforms and prevent overturning must be used.

(7) Mobile ladder stands and platforms that have wheels or casters are equipped with a system to impede horizontal movement when an employee is on the stand or platform.

(8) You must ensure mobile ladder stands and platforms are not moved while an employee is on them.

PDF296-876-91010

Design requirements for mobile ladder stands.

You must ensure:

(1) Steps are uniformly spaced and arranged, with a rise of not more than ten inches (25 cm) and a depth of not less than seven inches (18 cm). The slope of the step stringer to which the steps are attached must not be more than sixty degrees, measured from the horizontal.

(2) Mobile ladder stands with a top step height above ten feet (3 m) have the top step protected on three sides by a handrail with a vertical height of at least thirty-six inches (91 cm); and top steps that are twenty inches (51 cm) or more, front to back, have a midrail and toeboard. Removable gates or nonrigid members, such as chains, may be used instead of handrails in special-use applications.

(3) The standing area of mobile ladder stands is within the base frame.

PDF296-876-91015

Design requirements for mobile ladder stand platforms.

You must ensure:

(1) The steps of mobile ladder stand platforms meet the requirements of WAC 296-876-91010(1). When the employer demonstrates that the requirement is not feasible, steeper slopes or vertical rung ladders may be used, provided the units are stabilized to prevent overturning.

(2) Mobile ladder stand platforms with a platform height of four to ten feet (1.2 m to 3 m) have, in the platform area, handrails with a vertical height of at least thirty-six inches (91 cm) and midrails.

(3) All ladder stand platforms with a platform height above ten feet (3 m) have guardrails and toeboards on the exposed sides and ends of the platform.

(4) Removable gates or nonrigid members, such as chains, are only permitted to be used on mobile ladder stand platforms, instead of handrails and guardrails, in special-use applications.