PDFWAC 173-160-221

What are the standards for sealing materials?

(1) Bentonite sealant:

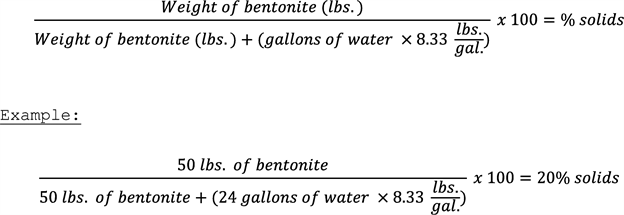

(a) Bentonite used to prepare slurries for sealing or decommissioning shall be specifically designed for this purpose. All bentonite slurries shall be prepared and installed according to the manufacturer's instructions. Active solids content (bentonite) shall be twenty percent by weight or greater in all bentonite slurries. The active solids shall be checked by using the following formula:

|

(b) Unhydrated bentonite including pelletized, granulated, powder, or chip bentonite may be used in the construction of seals or in decommissioning of wells. The bentonite material shall be specifically designed for sealing or decommissioning and be within the industry tolerances for dry western sodium bentonite. Placement of bentonite shall conform to the manufacturer's specifications and result in a seal free of voids or bridges.

(c) All bentonite used in any well shall be certified by NSF/ANSI approval standards for use in potable water supply wells, or equivalent standards as approved by the department. The product shall be clearly labeled as meeting these standards.

(2) Cement sealants:

(a) Neat cement consists of either portland cement types I, II, III, or high-alumina cement mixed with not more than six gallons of potable water per sack of cement (ninety-four pounds per sack).

(b) Neat cement grout consists of neat cement with up to five percent bentonite clay added, by dry weight of the bentonite. Bentonite is added to improve flow qualities and compensate for shrinkage.

(c) Concrete sealants consist of clean, hard and durable aggregate with not less than five sacks (ninety-four pounds per sack) of portland cement per cubic yard of concrete sealant and water.

(i) The maximum diameter of aggregate particles may not exceed 1 1/2 inches, but in any case may not exceed 1/5 the minimum width of the casing thickness.

(ii) The ratio of coarse aggregate to fine aggregate (passing No. 4 U.S. Standard Sieve) must be approximately 1 1/2 to 1 by volume, but in any case, may not exceed 2 to 1 nor be less than 1 to 2.

(iii) The quantity of water used for each batch of cement sealant shall not exceed manufacturer's recommendation.

(d) Expanding agents, such as aluminum powder, may be used at a rate not exceeding 0.075 ounce (1 level teaspoon) per sack (ninety-four pounds per sack) of dry cement. The powder may not contain polishing agents. High-alumina cement and portland cement of any type must not be mixed together.

(e) Controlled density fill (CDF) or fly ash shall not be used in any well construction or decommissioning.

(f) All cement sealants shall be mechanically mixed prior to placing in the well or bore hole.

(3) Sealing methods:

(a) When neat cement or neat cement grout is used in sealing, it shall be placed seventy-two hours before additional drilling takes place, unless special additives are mixed with the neat cement or neat cement grout that cause it to set in a shorter period of time.

(b) All hydrated sealing materials shall be placed by tremying the mixture from the bottom of the annular space to the surface in one continuous operation.

(4) This section may not preclude the use of new sealant materials which have been approved by the technical advisory group.

(5) Sealing materials shall be impervious to any contaminants encountered.

[Statutory Authority: Chapter 18.104 RCW. WSR 09-01-125 (Order 08-10), § 173-160-221, filed 12/19/08, effective 1/19/09; WSR 06-23-121 (Order 06-08), § 173-160-221, filed 11/21/06, effective 12/22/06. Statutory Authority: Chapter 18.104 RCW and RCW 43.21A.080. WSR 98-08-032 (Order 97-08), § 173-160-221, filed 3/23/98, effective 4/23/98.]